For centuries, metal maintenance has been a labor-intensive process requiring tedious manual scrubbing and grinding. However, with the invention of laser cleaning machines in recent years, metal maintenance has become quicker and more efficient than ever before.

Nowadays, these powerful machines can remove rust, paint coatings, oxides, and contamination from all kinds of metals without damaging the material underneath. They are also capable of removing both organic and inorganic materials from a variety of surfaces in an eco-friendly way that is easy on operator health.

In this article, we will explore how laser cleaning machines have revolutionized metal maintenance by providing an incredibly effective solution to age-old problems.

Introduction to Laser Cleaning Machines

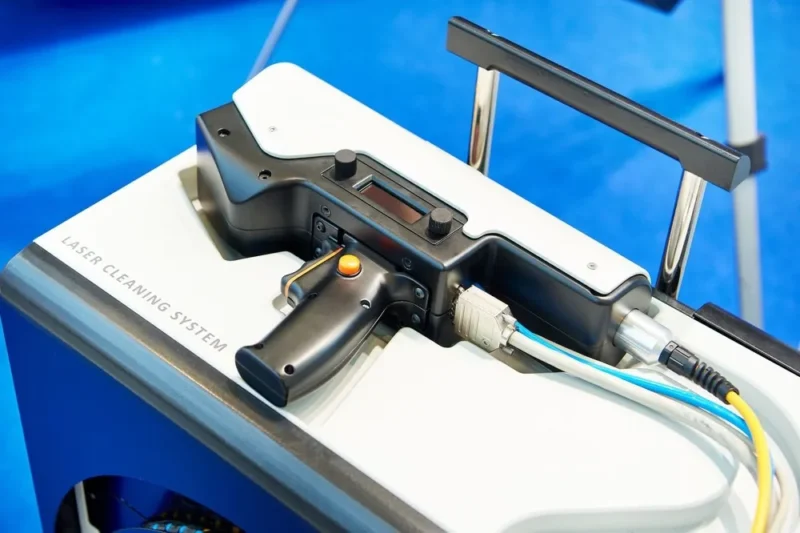

The introduction of laser cleaning machines has revolutionized the way metal maintenance is performed. Laser cleaning machines are equipped with powerful lasers that can quickly and efficiently clean a wide range of metals, from stainless steel to aluminum.

This technology offers significant advantages over traditional methods such as chemical cleaning or manual scrubbing; it is faster, more efficient, and produces superior results. As a bonus, laser cleaning also requires less energy than other methods while producing far fewer hazardous materials.

In this article, we\’ll look at how laser cleaners work and why they\’re so effective at metal maintenance. We also explore some of the benefits that this revolutionary technology provides for businesses working in the industry today.

Benefits of Laser Cleaning Machines in Metal Maintenance

Laser cleaning machines have revolutionized metal maintenance for numerous industries, offering a host of benefits that make it the preferred choice for many. These include increased safety, faster completion times, and improved accuracy.

Safety is a major concern when it comes to metal maintenance, but laser cleaning machines can eliminate any potential hazards. The lasers used in these systems are designed to minimize contact with the surface being cleaned by burning off dirt and grime without ever having to touch the item itself.

This greatly reduces the chances of an accident occurring on-site or of damage being caused by traditional methods such as sandblasting or chemical cleaners. The speed at which laser cleaning machines can operate is another advantage they offer over traditional methods when it comes to metal maintenance projects.

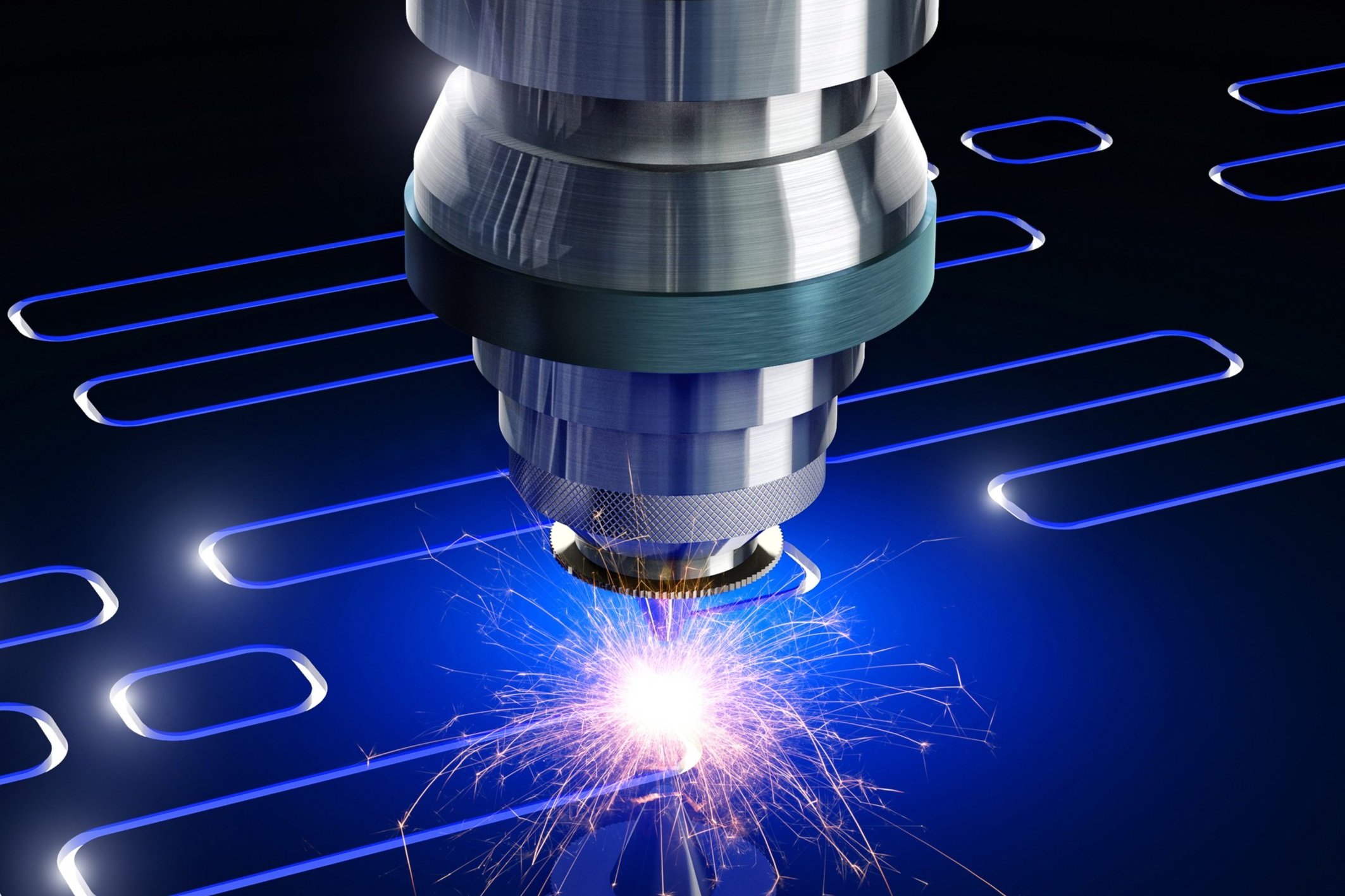

With minimal setup time and no need for manual labor once initiated, laser cleaning tasks often take less than half the time compared to conventional techniques such as grinding or hand scrubbing surfaces before painting them again. Finally, one of the most significant advantages offered by laser cleaning technology is its precision when removing deposits from surfaces like metals and alloys without damaging them in any way whatsoever – something not always achievable through traditional approaches like abrasive blasting or air blow-off solutions due to their lack of control over how much material gets removed from each pass across a given area.

In addition, since lasers only target specific areas where there are contaminants present while leaving untouched everything else around it, this results in greater efficiency during cleanup operations since operators don’t waste time trying to clean patches that weren’t affected anyway – saving both money and resources too!

Advantages of Using a Laser Cleaning Machine over Traditional Methods

Laser cleaning machines have revolutionized the way metal maintenance is done, providing clear advantages over traditional methods. Compared to pressure washing and chemical solvents, laser cleaning requires no additional support equipment or hazardous chemicals, saving time and money.

Laser cleaning is also much faster and more precise than traditional techniques. It removes rust, paint, scale buildup, corrosion, and other coatings quickly with minimal effort on the part of the operator.

The process can be precisely controlled to remove a certain amount of material from specific areas without damaging surrounding surfaces or affecting nearby components in any negative way. This makes it ideal for intricate parts that require meticulous care during maintenance operations.

Additionally, laser cleaning produces little-to-no secondary waste compared to conventional methods which generate runoff that must be collected for proper disposal afterward; this further reduces labor costs associated with cleanup activities after a job is finished.

The Future of Laser Cleaning Machine Technology

The future of laser cleaning machines promises to revolutionize the way metal maintenance is conducted. As technology continues to advance, so will its capacity for precision and accuracy in cleaning metals.

With improved optics that can precisely target specific areas, combined with more powerful lasers, it will be easier than ever before to safely clean away dirt and debris from intricate parts without damaging materials or surrounding components. Additionally, faster scanning speeds and smaller footprints are making these machines increasingly accessible to a variety of industries.

Newer technologies such as ultrasonic vibration cleaners are also being developed that could further reduce time spent on tedious tasks like surface preparation while offering improved effectiveness compared to traditional mechanical methods. With all these advancements, laser cleaning machine technology is sure to become even more indispensable in maintaining metal surfaces both now and in the future.

Conclusion

Laser cleaning machines are revolutionizing metal maintenance, making it easier and more cost-effective than ever before. With the help of these powerful devices, businesses can clean metals quickly and efficiently with minimal waste and effort. The laser technology used in these machines is precise, allowing for a perfectly clean surface without any damage to the metal itself.

This makes them ideal for use in industrial settings such as manufacturing plants or other areas where precision is important. In addition to being able to clean metals faster and more accurately than traditional methods, laser cleaning machines also have improved safety features that protect users from potential hazards associated with using lasers.

Overall, laser cleaning machines are revolutionizing metal maintenance by providing an efficient solution that saves time and money while ensuring the highest quality results possible.