When it comes to motor starters, there are a variety of options available. From Direct On-Line (DOL) to Star-Delta, the range of choices can be overwhelming, and understanding the differences between them is key for any engineer or technician looking for just the right solution.

This article, will take a closer look at each type of starter and explore their respective features and functions to help you make an informed decision.

Direct On-Line Motor Starter

A Direct On-Line Motor Starter is a type of motor starter commonly used in industrial settings. It allows for an electric motor to be directly connected to the main power supply without any intermediate devices, such as contactors or relays.

This type of setup has several advantages over other types of starters, including improved safety and reduced energy consumption. Additionally, it provides more precise control than other methods due to its direct connection with the power source.

The Direct On-Line Motor Starter can also be set up quickly and easily compared to other systems. Its versatility makes it suitable for a wide range of applications that require high levels of reliability and precision control.

Reduced Voltage Starters

A Reduced Voltage Starter (RVS) is a type of motor starter that helps reduce the inrush currents associated with electric motors. It works by gradually increasing the voltage supplied to the motor, allowing it to reach its full speed and power without causing an overload.

RVS starters are highly efficient and can help extend the life of your electric motor over time. They also provide greater protection against short circuits or other potential electrical problems that could damage your equipment.

In addition, they can offer cost savings due to their ability to limit energy usage when running at lower speeds. RVS starters come in many sizes and configurations, making them suitable for most industrial applications where large volumes of electricity may be required.

Variable Frequency Drives (VFD)

Variable frequency drives (VFD) are a type of motor starter that can provide significant advantages over traditional starting methods. VFDs use an adjustable frequency to vary the speed and torque of the motor, allowing for more efficient operation than traditional starters.

This makes them ideal for applications such as pumps, fans, compressors, and conveyor belts where varying speeds are needed. The primary advantage of using a VFD is that it can be adjusted on the fly with minimal energy losses due to its ability to adjust both voltage and frequency simultaneously.

Additionally, VFDs offer greater protection against overloads by providing precise control over the current draw from motors or other loads connected to them. This helps protect these systems from damage due to excessive current draw or heat buildup caused by prolonged usage at higher speeds without proper cooling.

Static Starters

Static starters are an important part of motor starter technology, providing a reliable way to start and stop motors. They provide a cost-effective solution for many applications, especially when the motor or system requires frequent starts and stops.

Static starters can be divided into two main types – Direct On-Line (DOL) and Star-Delta (SD). The DOL starter is the simplest type of static starter and works by connecting the supply directly to the motor windings.

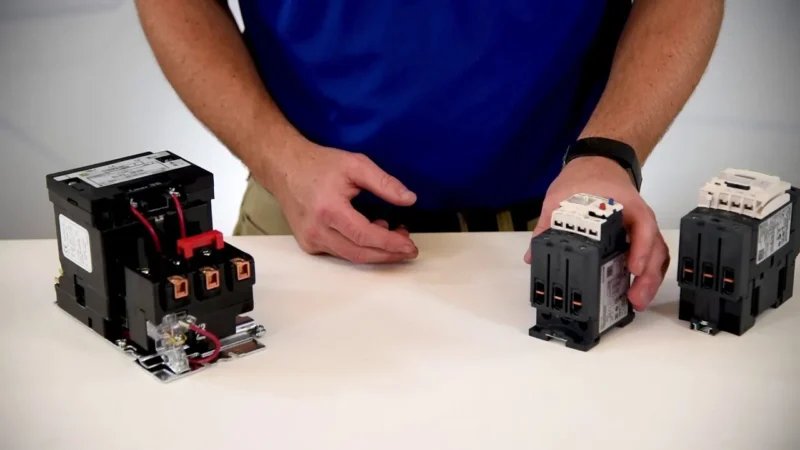

This is known as ‘direct online’ because it involves no other components between the power source and motor windings. The advantage of this type of static starter is its simplicity; it only comprises three contactors so installation costs are lower than more complex alternatives.

It also offers good protection against overloads due to its current limiting feature which prevents damage from high inrush currents experienced at startup. However, there are certain disadvantages associated with DOL starters such as poor starting torque performance due to the direct connection between supply voltage and motor winding resistance, resulting in slower acceleration times compared to other methods such as star delta starters discussed below.

Star Delta (SD) starters offer better performance than DOL for larger motors due to their ability to reduce starting currents while still providing sufficient torque for operation under heavy load conditions without causing excessive wear on mechanical parts like bearings or gears during startup periods. SD uses a combination of transformers, contactors, resistors, capacitors, timers, etc.

, allowing greater control over starting parameters such as ramp-up time, phase angle adjustment, maximum current limiting, etc., making them suitable for applications requiring higher levels of speed regulation or where energy efficiency is paramount.

These types of static starters require more complicated wiring arrangements than their simpler counterparts but they offer improved levels of protection against short circuits at startup along with increased versatility which makes them the ideal choice in many industrial contexts where precise control over process variables must be maintained continuously throughout production cycles.

Conclusion

Motor Starters are essential components for any motor-driven system, providing a controlled start-up and shut-down of the motor. From direct online starters to star-delta, these devices allow for safe operation of electric motors in many applications.

With the wide variety of Motor Starter types available, it is important to take into consideration the specific requirements of each application before making a decision. This article has provided an overview of the different types of Motor Starters and their unique features, allowing you to make an informed choice that will ensure optimal performance with long-lasting reliability.