Individual Quick Freezing (IQF) technology represents a significant advancement in the freezing of a wide array of food products. IQF tunnel freezers are essential for producing individually quick frozen products and are notable for their speed, efficiency, and the quality of the output they produce. The process involves rapidly freezing individual pieces of food – such as fruits, vegetables, seafood, and poultry – by passing them through a tunnel where they are exposed to extremely low temperatures. This rapid freezing process, often carried out by a cryogenic medium like liquid nitrogen or carbon dioxide, ensures that the frozen pieces are not clumped together and maintains the quality, texture, and nutritional content of the food.

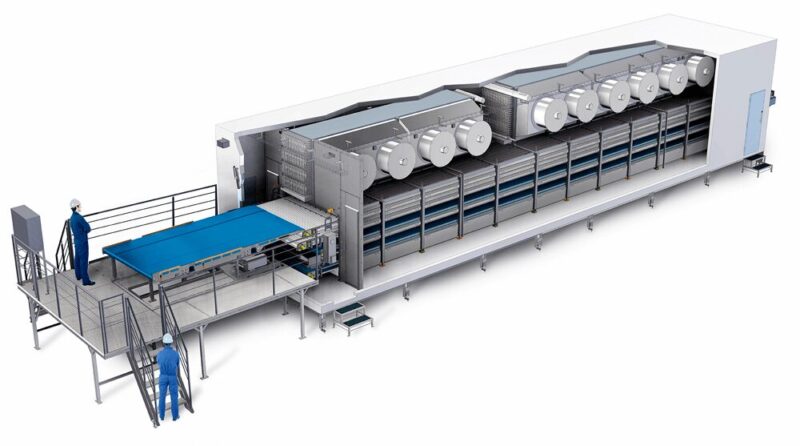

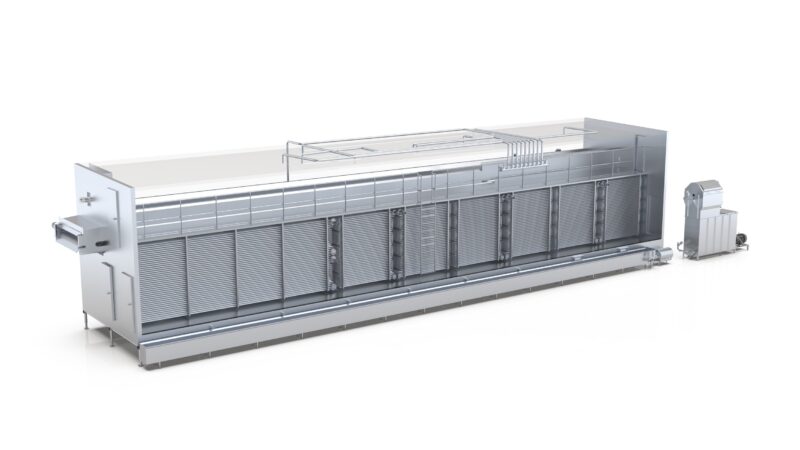

Tunnel freezers are designed with hygiene and handling efficiency in mind, enabling high-throughput processing that is gentle on the product. This is particularly beneficial for delicate food items that are prone to damage when handled roughly. Innovations like Long Wave Fluidization™, used in some models, enhance the freezing process by promoting optimal heat transfer and preserving the physical integrity of the food.

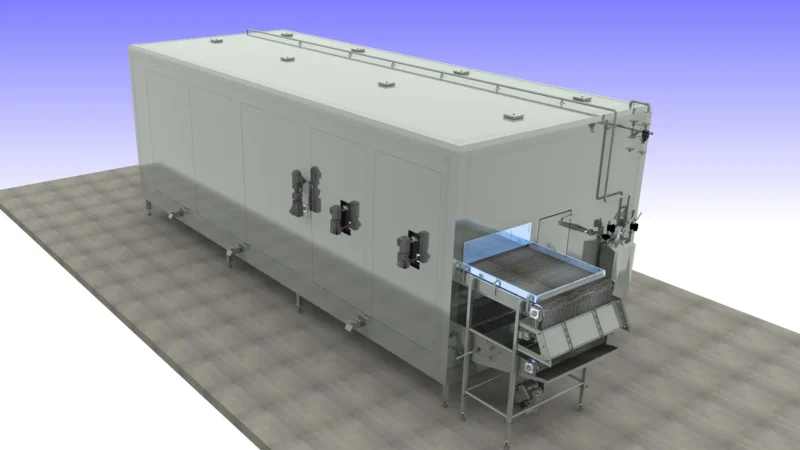

The versatility of IQF tunnel freezers makes them suitable for a wide range of products and integral to food producers looking for high-yield solutions. The compact design of certain tunnel freezer models allows for effective use of space within production facilities, with some designs up to 50% smaller than traditional freezers without compromising production capacity. This leads to diverse applications in the food industry and reflects an ongoing drive towards developing technology that meets various production needs without inflating operational costs.

Understanding IQF Tunnel Freezers

Individual Quick Freezing (IQF) tunnel freezers are essential for preserving the quality of a wide range of food products by rapidly freezing them to minimise cellular damage. This innovative technology ensures food retains its shape, texture, colour, and flavour.

Fundamentals of the Freezing Process

In an IQF tunnel freezer, food items are spread on a conveyor belt and passed through a tunnel where they are quickly frozen by blasts of extremely cold air. The speediness of the process generates small ice crystals that preserve the cellular structure of the food, maintaining quality and freshness.

Technological Advancements and Innovations

IQF technology has evolved with features such as multiple temperature zones and gentle handling of products, contributing to high efficiency and flexibility. The sectors of the freezer can be adjusted to fit specific freezing demands, enhancing the IQF quality of a diverse assortment of foods.

Comparative Analysis: Cryogenic Vs Mechanical Freezing

While cryogenic freezers utilise liquid nitrogen or carbon dioxide for rapid chilling, mechanical IQF tunnel freezers employ traditional refrigeration methods. The longevity and lower operation costs associated with mechanical freezers often make them a more economical choice over cryogenic options.

Optimising for Different Food Types

IQF tunnel freezers can adapt to different foods such as fruit, vegetables, berries, shrimp, and meat products. The ability to finely control the temperature and airflow affords tailored preservation methods for each food type, ensuring optimal freezing quality.

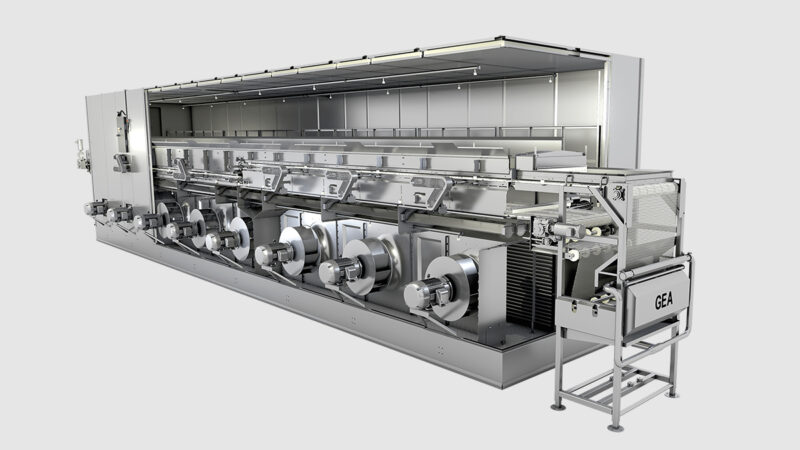

Industry Compliance and Enhancing Food Safety

Constructed from stainless steel, IQF tunnel freezers offer high hygiene standards necessary for compliance with stringent food legislation. They are designed with ease of cleaning in mind, playing a pivotal role in providing safe food handling and storage.

Economic Considerations and Maximising ROI

Utilising an IQF tunnel freezer can greatly increase product yield and efficiency. Investment in this technology can lead to substantial cost savings over time due to reduced downtime, efficient use of space with a small footprint, and lower energy consumption.

Supporting the Cold Chain with Advanced Solutions

A reliable cold chain management system is critical for maintaining food freshness from processing to market. IQF tunnel freezers excel at integrating with cold chain solutions to deliver preserved produce that meets customer expectations for quality and safety.

Adding Value Through Service Expertise

Manufacturers of IQF tunnel freezers often provide additional services such as consultancy, process evaluation, and training support. These expert services ensure manufacturers get the most out of their equipment and adapt quicker to technological advancements.

IQF Freezing and the Environment

Sustainable refrigeration technologies are now more than ever integral to environmental responsibility within the industry. IQF tunnel freezers are being developed to use less energy and incorporate environmentally friendly practices into their operation.

Adapting to Production Volumes and Seasonality

IQF tunnel freezers are designed to efficiently manage varying production volumes, offering the flexibility necessary to handle peak seasons and product fluctuations without compromising on freezing capacity or quality.

Navigating Through Technology and Scaling Up

Scaling operations to meet growing market demands can pose challenges. IQF tunnel freezers are scalable solutions that can be seamlessly integrated into an existing freezing process, allowing businesses to expand their capability strategically.

The Role of Education and Information in the Sector

Education is key in keeping the food industry abreast with technological evolutions. Manufacturers and food processors benefit from valuable resources like GEA insights, which offer videos and downloads to keep them informed about the latest developments.

Partnering for Success in Freezing Technologies

Collaborations between food processors and technology providers foster innovation in the industry. For high-quality IQF equipment for shrimp processing, the IQF Tunnel Freezer is an example of a specialised freezing solution designed for maritime and onshore applications.

Understanding Global Trends and Market Demand

Being aware of global consumer trends and market demand is essential for aligning product offerings with consumer expectations. IQF tunnel freezers align with the food industry’s needs by accommodating different food types and adapting to technology trends.

Future of IQF Freezing: The Road Ahead

With advances in automation and energy efficiency, the future of IQF tunnel freezers looks promising. The demand for high-quality frozen foods is likely to drive further innovations, ensuring that this technology remains at the forefront of the food industry innovation and maintains its role in safeguarding food quality.