From the creation of intricate sculptures to the forging of industrial components, steel casting foundries have been at the heart of metalwork for centuries. Every step in the process is a delicate balance between art and engineering, requiring an eye for detail and an understanding of metallurgy.

Unveiling the craftsmanship that goes into these production processes can be a challenge; however, it’s essential to appreciate what it takes to produce strong and reliable parts from raw materials. In this article, we will explore how a steel-casting foundry produces strength by taking raw materials through a series of complex steps involving both precision and power.

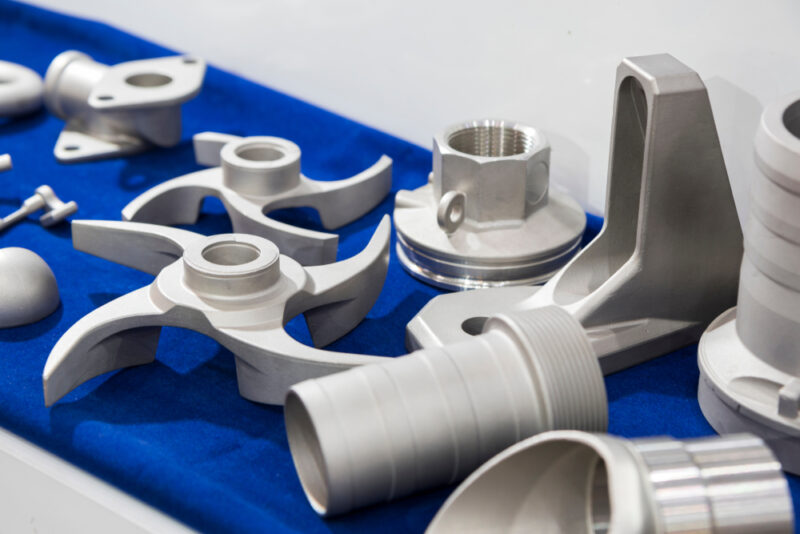

From heat treatment techniques to advanced 3D printing technologies, each part is crafted with care using state-of-the-art machinery to reach its optimal strength potential. Join us as we take you on an inside look at what makes up a successful steel casting foundry – revealing their secrets for forging strength!

Celebrating the Expertise of Steel Casting Foundries

The art and skill of steel casting foundries have been around for centuries, and their craftsmanship is something to be admired. Their technical expertise allows them to turn molten metal into intricate shapes with incredible precision, creating products that are as beautiful as they are durable.

From architecture and engineering projects to custom-made sculptures, these foundries bring an unparalleled level of quality to whatever material they work on. They have perfected techniques through trial and error over generations, making sure each piece is crafted with care to last a lifetime or longer.

Foundry workers must possess an immense amount of knowledge about metallurgy to ensure that each project not only looks great but also performs optimally under any conditions. This level of mastery takes years upon years of dedication; it’s no wonder why many consider them experts at what they do! Through the use of modern technology such as computer numerically controlled (CNC) machinery, these skilled professionals can produce exact replicas with unprecedented accuracy while still leaving room for artistic flair when necessary.

Despite all the advancements made in recent times, much remains unchanged from centuries ago – namely, the commitment required by those working within this profession: devotion to detail and pride in one’s work remains paramount if success is desired. By celebrating these talented individuals we honor their hard work and acknowledge how integral their presence has been throughout history – today more than ever!

Exploring the Strength and Resiliency of Steel Casting

Steel casting is an art form that combines strength and resiliency, making it a powerful tool in the fabrication of numerous products. From industrial parts to intricate sculptures, steel casting has been used for centuries to create some of mankind’s most impressive works.

As technology advances and new techniques are developed, steel casting continues to be one of the most reliable ways to craft durable items that will stand up to the test of time. The process starts with creating a mold from a pattern or by using lost wax methods.

Once the mold is created molten metal is poured into it to make a replica of whatever was formed inside its walls. After shaping and finishing, each piece undergoes rigorous testing before being approved for sale.

This ensures that customers receive only high-quality castings made with precise attention to detail and expert craftsmanship. By exploring the strength and resiliency of steel castings we can gain insight into what makes them so dependable and why they’re still widely used today despite modern alternatives such as 3D printing or plastic injection molding becoming increasingly popular choices for manufacturing products on larger scales.

Unlocking the Secrets Behind Forging Strength

At the heart of any steel casting foundry is a mastery of craftsmanship. Unlocking the secrets behind forging strength requires an understanding of how these techniques are employed and why.

From the heat treatment used to create durable, strong metal alloys to specialized molding processes that result in intricate shapes and designs, each step plays an essential role in crafting a finished product with unmatched strength. By taking a closer look at each stage involved in creating steel castings—from design to production—we can uncover how this age-old process continues to produce some of the strongest materials available today.

We can also learn what makes steel castings so much stronger than other traditional manufacturing methods, such as machining or welding. By exploring these topics further, we gain insight into why steel casting remains one of the most reliable ways to form parts from molten metals while ensuring optimal performance for even the most demanding applications.

Conclusion

Steel castings are some of the most resilient and durable components of our modern world. The process to make them is complex, requiring skillful craftsmanship, experience, and specialized equipment.

Forging Strength LLC has been producing quality steel casting for over two decades in their foundry located in the heart of Illinois. With a dedication to excellence and commitment to customer satisfaction, they have earned a reputation as one of the top metal casting companies in North America.

Their experienced team uses state-of-the-art technology combined with traditional methods that continue to produce superior results year after year. To learn more about how this remarkable company creates such strong and dependable products from raw materials, visit their website or contact them directly today!